I use the cutlist optimizer website whenever I am breaking down large sheet goods into individual parts and components. The website is easy to use, accurate. FastCUT® Optimizer - Metal/Wood/Glass. 1D/2D cutting optimizer and cut list generator for Rectangular, Linear or Stock Length materials cut with Shears or Saws. A ready reckoner for estimating and factory floor staff.

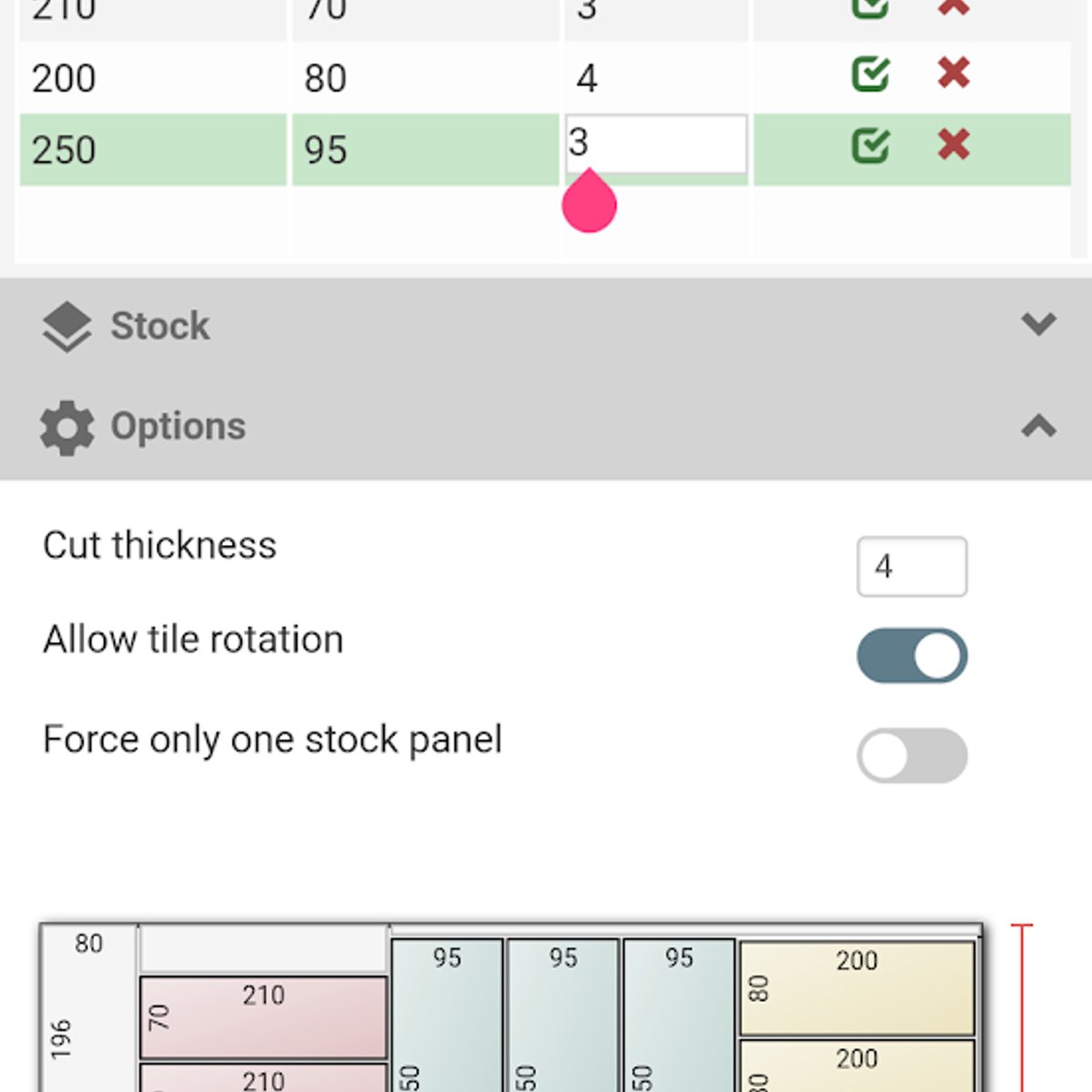

Powerful cutlist optimizer designed to find optimal cut layouts. Type the sheet length and width, cutting kerf and required panel sizes and quantities. Cutlist optimizer will generate optimal panel nesting plan in couple of seconds.

About this cut list optimizer

Cutlist Optimizer For Mac

This online cut list optimizer is kind of cutting optimization software specialized for cutting rectangular material like wood, glass or sheet metal. Easy to use plywood cut calculator.

In industry, 2D cutting stock problem is one of the most important tasks how to cut sheet material with maximal material yield and minimal waste. This cut list calculator will help you with this issue in real time with couple of clicks. Because cutting stock problem is a subclass of NP-hard problems, it is very time consuming to find optimal solution for complex tasks but also for fairly simple tasks. Heuristics and evolutionary algorithms are much better choice for complex problems. Our cut sheet calculator use these powerful methods so the final solution is really close to optimal solution or is optimal solution.

For hobbyists, tradesmen, small companies or for every personal or commercial entity, who do not require to solve complex sheet cutting optimization problems (when our Free plan is sufficient), we provides our cut optimizer completely FREE OF CHARGE.

Hey! Selphy cp800 driver for windows 10. I've finally built a replacement for this tool that I think is up to par. It includes some of your requests and should work well on mobile devices. Try out Cutlist Workbench and let me know what you think.

This calculator attempts to generate the most efficient cut list for a given set of pieces. Note my use of the word 'attempts.' There are several ways to solve this problem and several 'correct' answers. This tries one way and gives you a correct answer. It's based on linear board-feet and so works only in the one dimension. I may expand it to handle plywood at some point in the future but don't count on it.

| 1/32 | 0.03125 |

| 1/16 | 0.0625 |

| 3/32 | 0.09375 |

| 1/8 | 0.125 |

| 5/32 | 0.15625 |

| 3/16 | 0.1875 |

| 7/32 | 0.21875 |

| 1/4 | 0.25 |

| 9/32 | 0.28125 |

| 5/16 | 0.3125 |

| 11/32 | 0.34375 |

| 3/8 | 0.375 |

| 13/32 | 0.40625 |

| 7/16 | 0.4375 |

| 15/32 | 0.46875 |

| 1/2 | 0.5 |

| 17/32 | 0.53125 |

| 9/16 | 0.5625 |

| 19/32 | 0.59375 |

| 5/8 | 0.625 |

| 21/32 | 0.65625 |

| 11/16 | 0.6875 |

| 23/32 | 0.71875 |

| 3/4 | 0.75 |

| 25/32 | 0.78125 |

| 13/16 | 0.8125 |

| 27/32 | 0.84375 |

| 7/8 | 0.875 |

| 29/32 | 0.90625 |

| 15/16 | 0.9375 |

| 31/32 | 0.96875 |

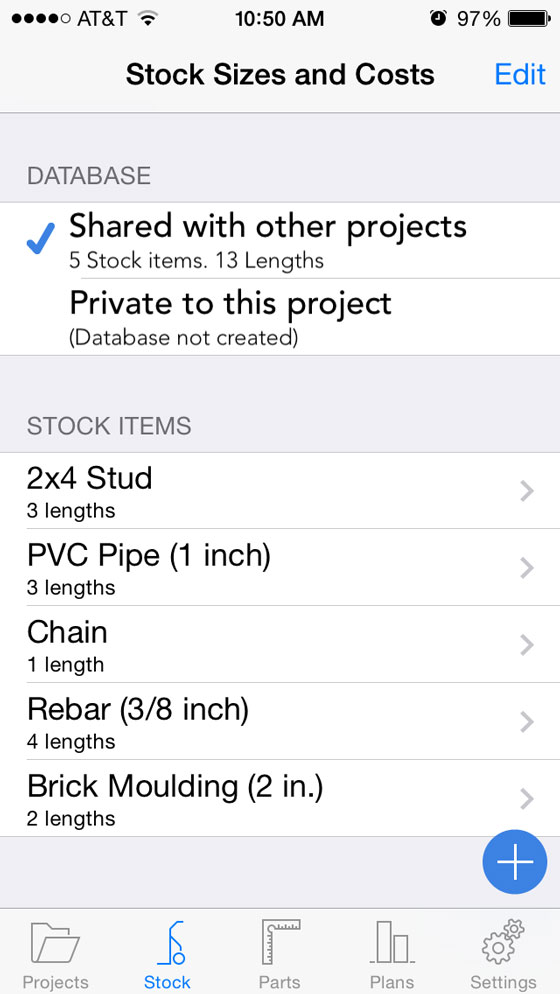

Step 1: Available stock - Select the available lengths:

Description:

Step 2: Method - Select which method you prefer:

Step 3: Cut Width - Enter how much of the board is lost to each cut (width of the blade):

'

Step 4: Piece List - Enter a list of board lengths you need to obtain:

| ID | Quantity | Length (in.) |

|---|---|---|

| ' |

Step 5: Output options:

Plywood Sheet Cut Layout

Step 6: Ready, steady,

Step 7: Once you're happy with your results, you might want to save or print them off. Set the 'Output to new window' option above and the results will go into a popup window.